TMC’s CleanTop Performance Optical Tables and Isolation Systems

TMC’s optical tables and isolation systems offer industry-leading performance and rigidity ……...

Evident’ 39DL PLUS™ gauge works as a precision or corrosion thickness gauge for demanding applications.

With world-class ultrasonic capability, fast scanning speeds up to a 60 Hz update rate, and fully integrated wireless connectivity, our flagship handheld thickness gauge delivers results you can trust in a seamless workflow.

Connected: Integrated Wi-Fi®, Bluetooth®, USB, RS-232, and a removable microSD card*

Fast: Scan for minimal thickness areas at a 2 times faster display update rate**

Versatile: Tackle multiple thickness applications with our full line of dual and single element transducers

*Wi-Fi®and Bluetooth®are pending certification in some regions. Contact your local Evident representative for details on their availability.**Up to 60 Hz versus 30 Hz on the predecessor model and comparable handheld thickness gauges.

Image Credit: Evident Corporation

Affordable Part Scanning

With breakthrough scanning speeds, the 39DL PLUS instrument offers an industry-leading*** 60 Hz update rate for handheld thickness gauges.

Works as an affordable alternativefor inspection codes that require a 60 Hz display update rate for scanning; get the scanning speed of a flaw detector with the ease of use of a thickness gauge

Find thin spots more easilywhen scanning for minimal thickness areas on pipes and other assets affected by corrosion

***As of June 2024.

One Thickness Gauge for Multiple Applications

Take advantage of powerful measurement features and a suite of application-specific software options for your current and future requirements.

|

Wide thickness range: 0.08 mm (0.003 in.) to 635 mm (25 in.) depending on material and transducer selection Corrosion thickness gaugingwith dual element transducers High Resolution software optionof 0.001 mm or 0.0001 in. with single element transducers from 2.25 MHz to 30 MHz THRU-COAT™ technologyand echo-to-echo measurements to measure through painted and coated surfaces Internal Oxide/Scale software optionfor boiler tube and internal oxide measurements Multilayer software optionto measure up to four layers simultaneously High Penetration software optionfor attenuating materials such as fiberglass, rubber, and thick castings |

Standard resolution: 0.01 mm or 0.001 in. for all transducers Thickness, velocity,andtime-of-flightmeasurements Differential modeandreduction rate modeto track thickness variation and its percentage from a preset value Time-based B-scan mode: 10,000 reviewable readings per scan High Dynamic Gaintechnology with digital filters optimizes the starting gain setting based on calibration V-Path Builderfor custom V-path compensation in corrosion applications Designed forEN15317 compliance Compatiblewith all probes and accessories supported on the predecessor model |

Key Benefits

Trusted Ultrasonic Technology

The 39DL PLUS gauge builds on proven performance. Confidently perform your work with industry standard technology for ultrasonic thickness testing.

Accurate, reproducible measurementsfrom exceptional signal quality, stable waveforms, and optimized algorithms

World-class ultrasonicsdeveloped by professionals with 35+ years of nondestructive testing (NDT) experience

Built to Last in Any Environment

Your thickness gauge needs to keep working despite shocks, drops, and rough handling, and the 39DL PLUS instrument is up to the challenge.

Rugged: Designed for IP67 for protection against dust and water

Explosive atmosphere, shock, and vibration testedusing MIL-STD-810H

Wide operating temperature range: –10 °C to 50 °C (14 °F to 122 °F)

Protective rubber bootwith gauge stand

Image Credit: Evident Corporation

Easy to Carry, Easy to Use

Designed with the operator in mind, the 39DL PLUS handheld gauge is comfortable to carry and use in the field or on the production floor.

Ergonomic keypad: operate with the left or right hand for quick access to all functions

Lightweight handheld design: Weighs only 0.83 kg (1.83 lb)

Built-in data logger: Easily collect thickness readings and waveform data

Efficient inspections: Default and custom setups for dual and single element transducers

Secure access control: Lock instrument features with password-protected functions

Excellent clarity: Color transflective VGA display with indoor and outdoor color settings

See work on a larger screen: VGA output to connect the gauge to a computer or monitor

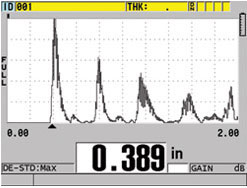

Outdoor display setting, A-scan mode

Indoor display setting, B-scan mode

Image Credit: Evident Corporation

Save Time with a Digital Inspection Workflow

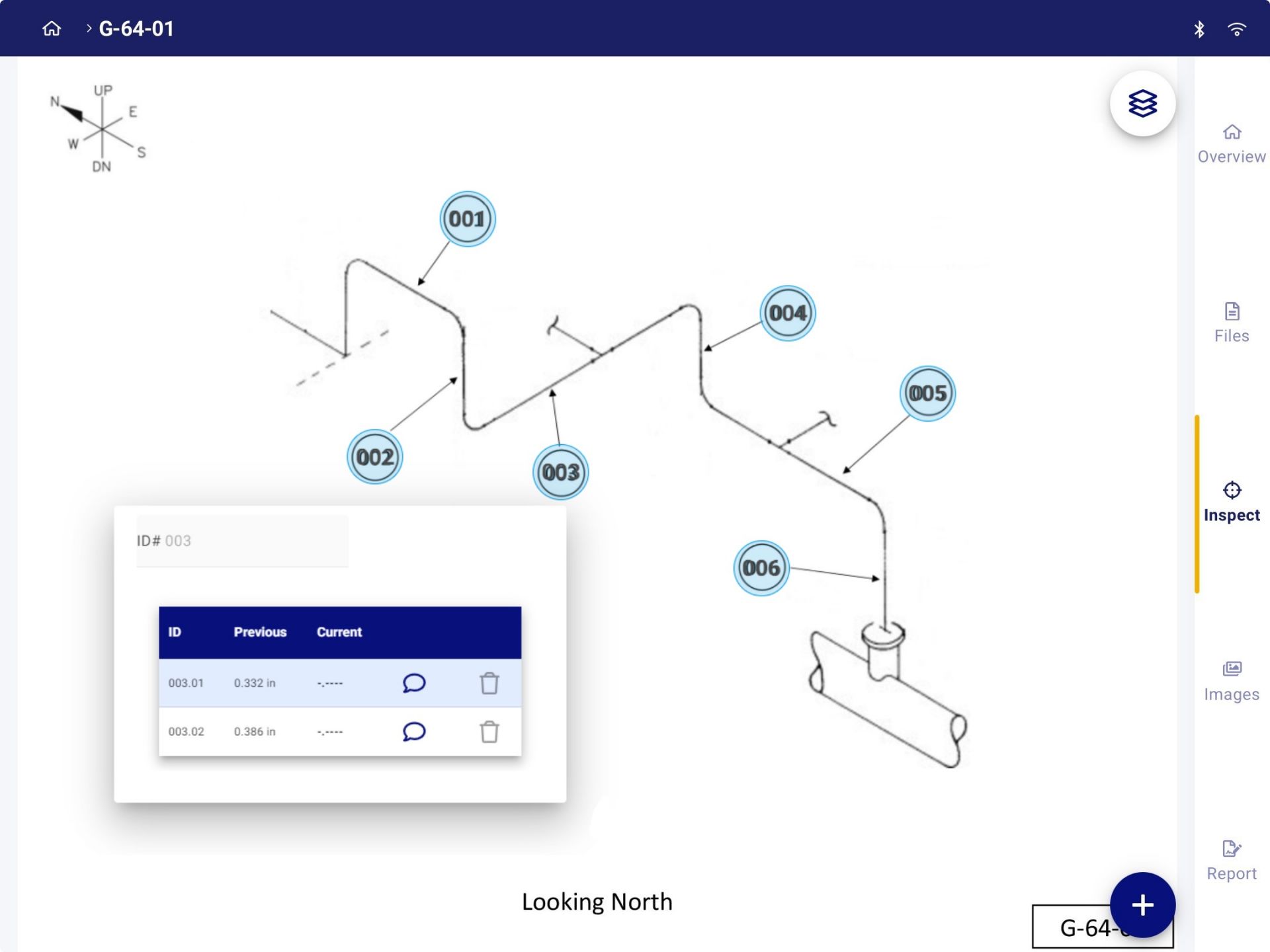

Integrated Wi-Fi®and Bluetooth®capabilities on the 39DL PLUS™ thickness gauge enable a seamless inspection workflow for Industry 4.0.

Wirelessly connect to the Link Plus iOS app, Link-Wedge software, or the Inspection Project Manager (IPM) app to effortlessly share results

Use GageView™ software for the flexibility to review data with a wired connection

Image Credit: Evident Corporation

Powerful Workflow Management Tools

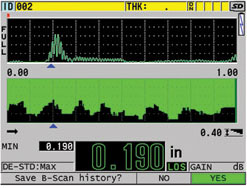

The Inspection Project Manager (IPM) is a cloud-based web and mobile app offering a digital inspection workflow that improves efficiency and data integrity.

Use the iOS or Android mobile app with or without an internet connection to efficiently execute inspection tasks

Collect inspection data and digitally sign off on inspection tasks in an intuitive interface

The digital report automatically updates throughout your inspection

Image Credit: Evident Corporation

|

Send Thickness Data to Your Mobile Phone or Tablet Use the Link Plus iOS app and Bluetooth® to send thickness data to your phone or tablet. From your mobile device, share thickness data over text message or email, or save the data as a text file for easy import to a spreadsheet You can also send data to compatible third-party mobile applications |

|||

|

Easily Populate Your Thickness Data into Data Entry Programs Use the optional Link-Wedge software and Bluetooth® to send data from your gauge to an active Windows software application. The software can populate data into almost any Windows-based data entry program. |

|||

|

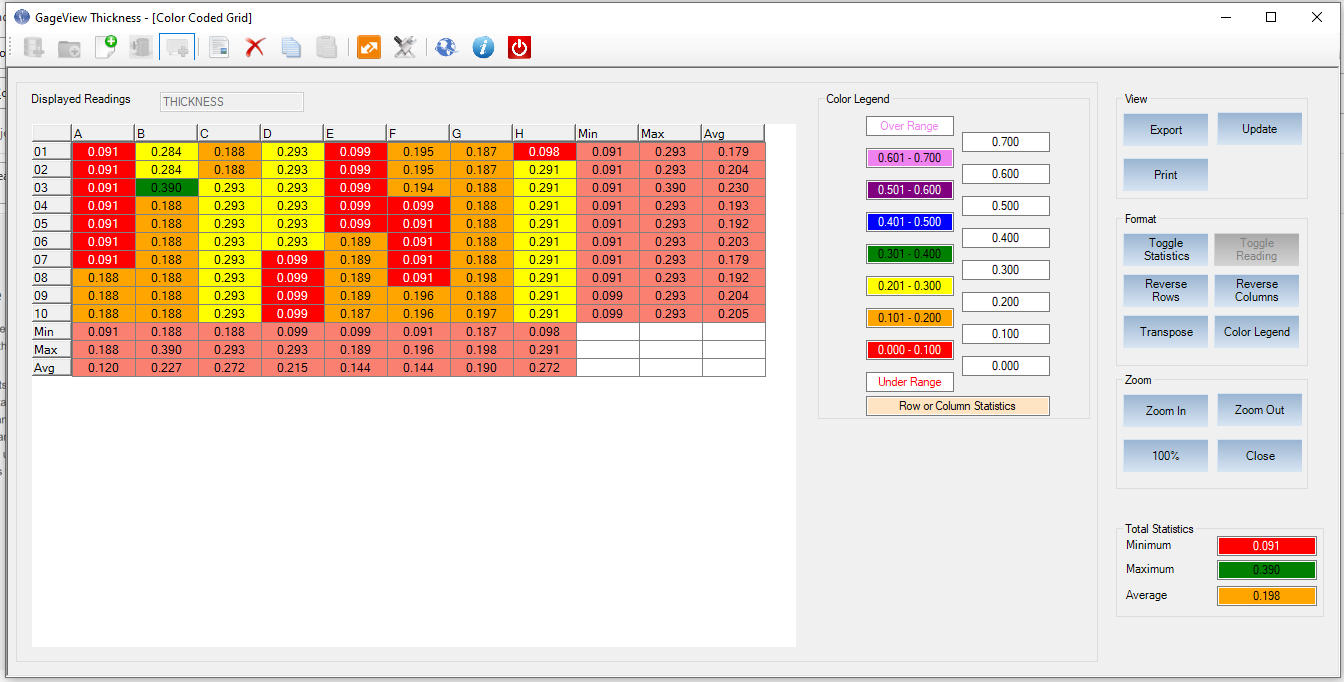

Remote Control and Integration The 39DL PLUS gauge offers the potential for remote control and integration, enabling convenient control of the gauge from a distance in innovative applications. To learn more about these capabilities, reach out to your local Evident sales representative. Confidence in Your Thickness Data Built-In Data Logger Improve productivity and data traceability with the full-featured, built-in data logger on the 39DL PLUS gauge. The bidirectional alphanumeric data logger is designed to easily collect and transfer thickness readings and waveform data. Log dataInternal memory of 792,832 thickness readings or 20,000 waveforms with thickness readings 32-character file name 9 file formats: incremental, sequential, sequential with custom point, 2D grid, 2D grid with custom point, 3D grid, 3D custom, boiler, and manual 20-character ID# (thickness measurement location or TML#) Store up to 4 notes per ID# Store notes at one or more ID#s Analyze data Onboard statistical report Assess readings at a glance: Onboard DB Grid View with three programmable colors set to specific thickness values Transfer data Wirelessly share data: integrated Wi-Fi® and Bluetooth® Wired data transfer: USB and RS-232 communication ports Two-way transfer of single and dual element transducer setups Copy files between internal/external microSD™ memory cards; directly export internal files to a microSD card in an Excel-compatible CSV format PC Software The GageView™ interface program, a Windows-based application, collects, creates, prints, and manages data from the 39DL PLUS gauge. The software communicates with the gauge using the USB and RS-232 ports, and it can read and write to a microSD memory card.

|

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such marks by Evident Corporation is under license.

TMC’s optical tables and isolation systems offer industry-leading performance and rigidity ……...

The ElectroForce® 5500 BioDynamic® test instrument has been designed for usage with custo……...

STOE develops, manufactures and sells scientific instruments for the non-destructive analysis of ……...

The multidrill XL is the best-selling model of Fraste. It has high performance, versatility, powe……...

/9-9-I-9M-9M-9-9A-9-9G-9G-9E-1/ Syft Technologies是实时直接注射质谱的世界领导者,具有超过20年的……...

Acacia Research Corporation comprises two operating groups, Acacia Technologies group and CombiMa……...

Item North America is a premier provider of precision ball screws for use as a drive mechanism in linear slides, multi-axis motion and complex material handling devices. item ball screws feature hi……

SurPASS™ 3 is capable of measuring the zeta potential over an extensive range of materials and allows the analysis of varied surface properties and their changes. The zeta potential explains ……

AHP Materials is a specialty materials company focused on the manufacturing and selling of high purity specialty metals and compounds. AHP concentrates mainly on Antimony, Cadmium Sulfide, Telluriu……